- Cart0

You have no items in your shopping cart.

-

Satisfaction

Guarantee -

Low

Price -

HIGH

SECURITY -

Customer

Support -

Ship

Worldwide

Western Digital USB-SATA PCB List

| Western Digital USB-SATA PCB List | |

| USB PCB | SATA PCB |

| WD 771675 | WD 771672 |

| WD 701615 | WD 701499 |

| WD 771737 | WD 771692 |

| WD 771761 | |

| WD 771754 | |

| WD 771801 | WD 771823 |

| WD 771859 | WD 771852 |

| WD 771814 | WD 771820 |

| WD 771817 | |

| WD 771949 | WD 771931, WD 771959 |

| WD 771962 | |

| WD 771950 | WD 771933, WD 771960 |

| WD 771961 | |

HD HPE PRO

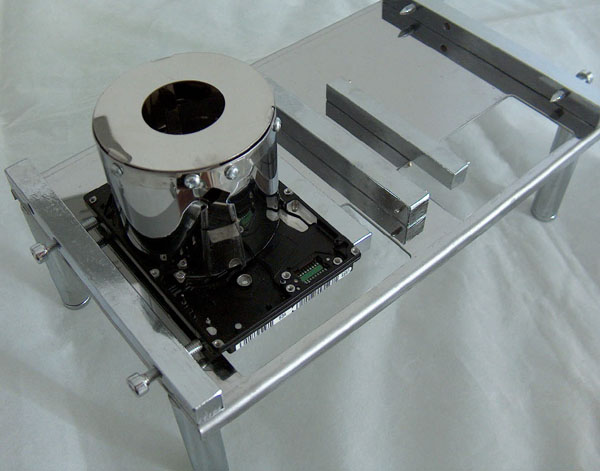

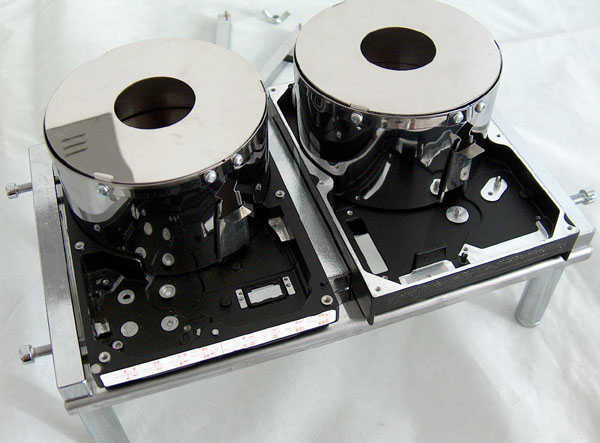

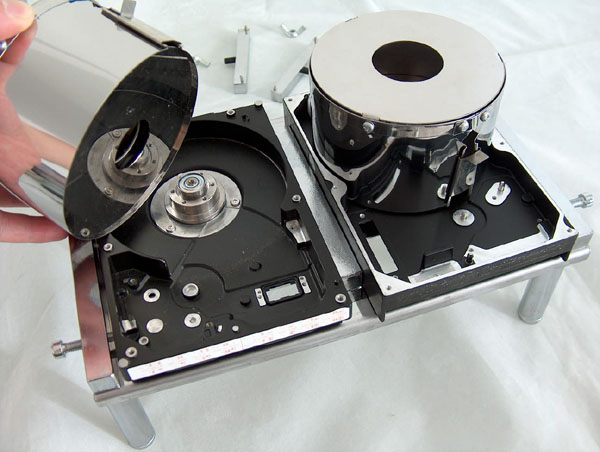

HD HPE PRO: A Must-Have hardware level of disk repair and data recovery equipment, which enables you an easy and exact drive disassembling and HEAD stack/Platter exchange.Highlights

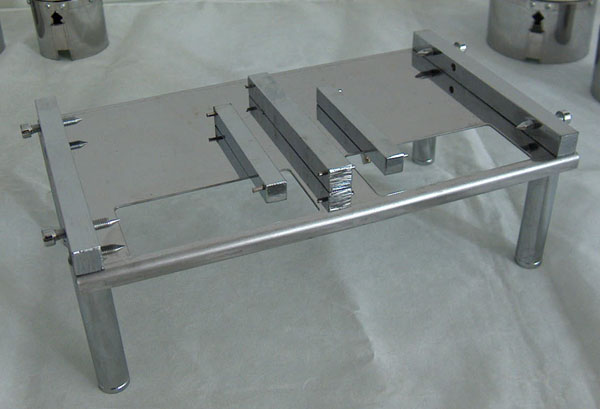

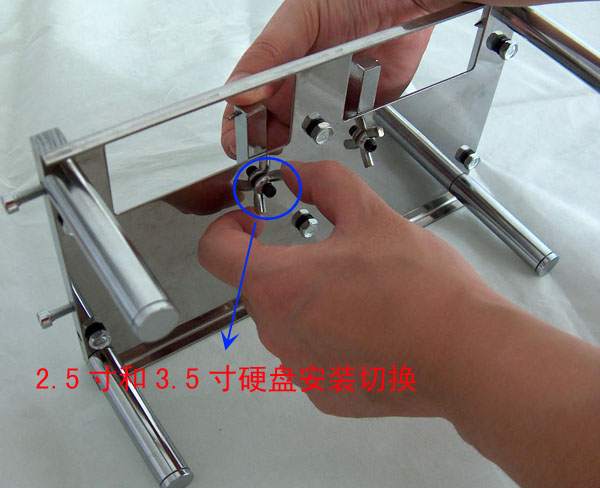

Universal-fit workbench assures you to operate on your HD on a relatively stable table, making your job easier and more reliable.

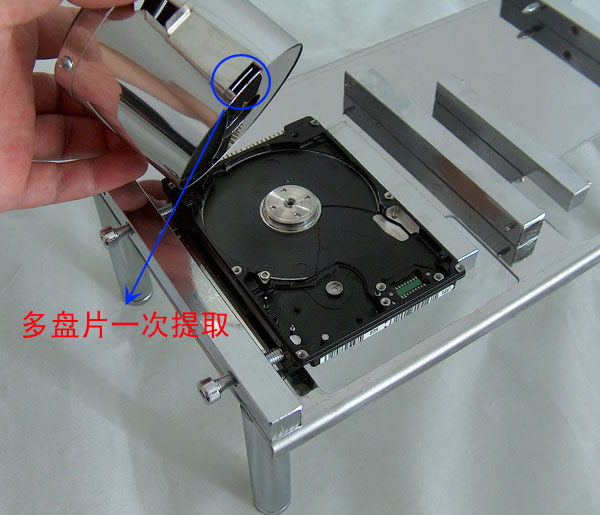

Pioneer platter exchanger maintains the original cylinder status by removing and placing each platter of the multiple platters together, so that allows you to change multiple platters without moving the platters out of alignment with each other which otherwise will result in data corruption.

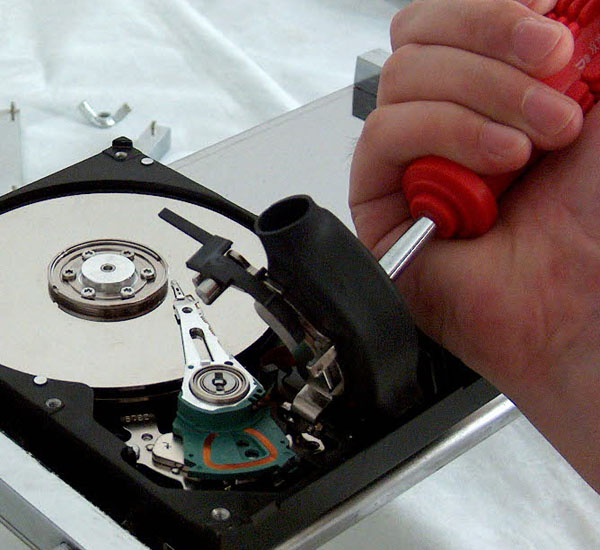

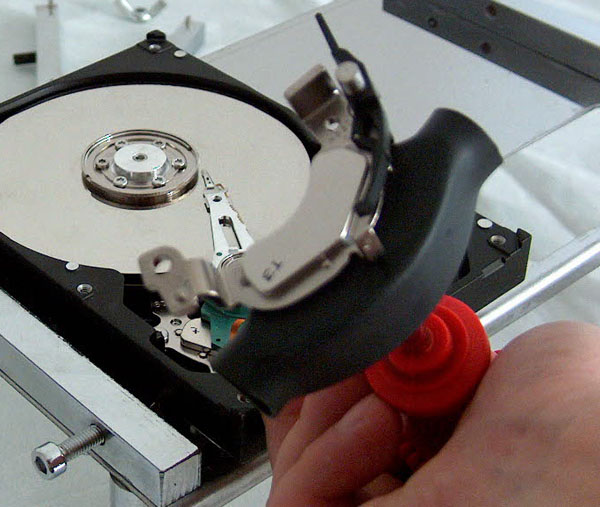

Special Actuator Remover assures you to perform easy operation (removal, installation) on the upper magnet of the actuator which is very hard to be removed and put back because of its strong magnetism and it’s sensitive and embarrassed position (being very close to both the Head Stack and Media Platter), in case it slips out and touch either of its fragile neighbors during the operations — the consequences will be a disaster.

PCB repair

The Printed Circuit Board controls many functions to operate the hard disk drive, There are 5 main features of a the electronics that can be unique to each drive that is likely to fail, the first being:

PCB Replacement

What is Hard Drive PCB?

The green board on the bottom of the hard drive is known as Printed Circuit Board(PCB). The main function of the PCB is to supply power to the hard drive, maintain speed and rotation of the spindle, and control all internal operations through its firmware. Essentially, PCB is the brains of the hard drive that all components are heavily dependent upon.

Why Swap Hard Drive PCB?

Hard drives that do not spin up after the power has been supplied can be diagnosed as PCB failure. Because data recovery service is very expensive, sometimes we would prefer to swap PCB ourselves.

How to find the matching Hard Drive PCB boards?

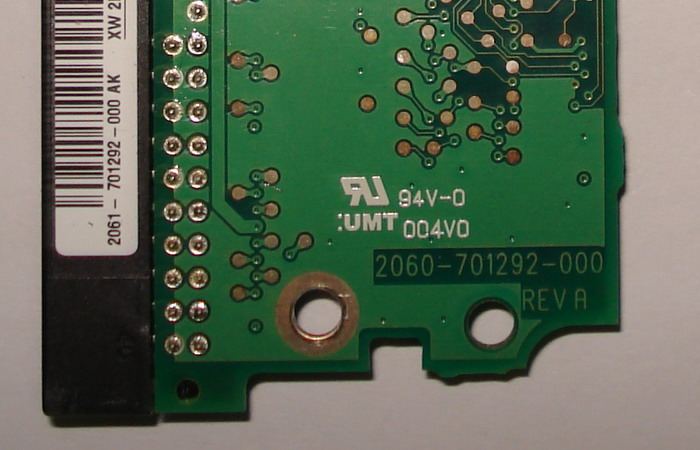

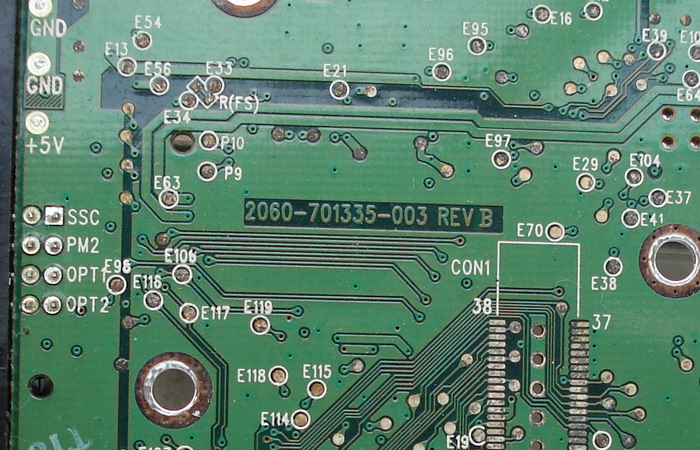

• Western Digital - same board number which is etched on the PCB, begin with 2060-, for example 2060-701292-002.

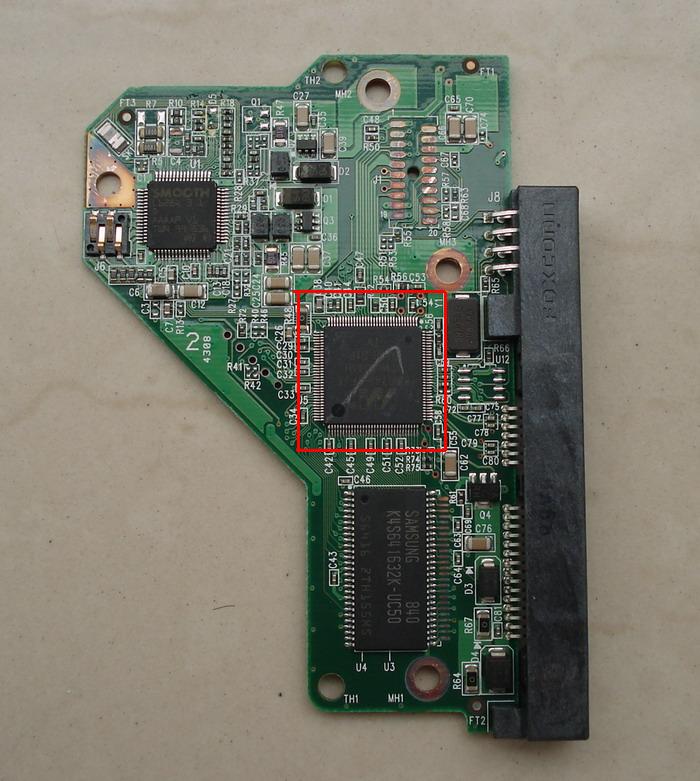

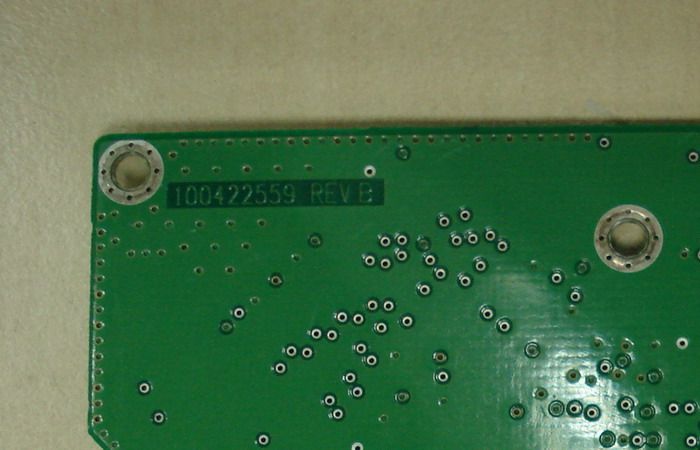

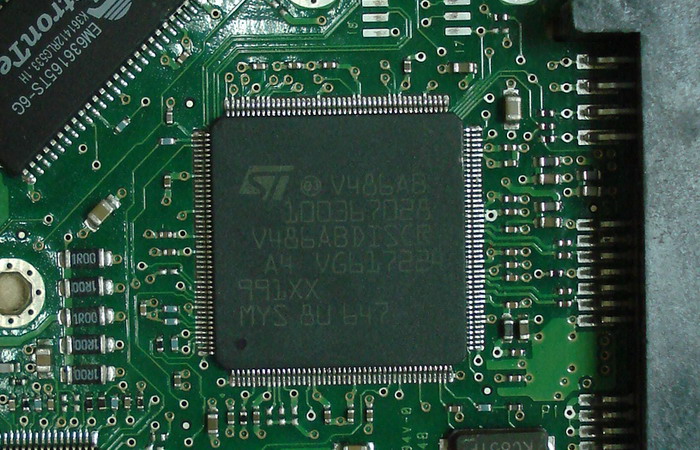

• Seagate - same board number which is etched on the PCB, begin with 100…, for example 100466725, and the same Main Controller IC. If you can’t find the number on the PCB (Old Models), you should find the same Main Controller IC.

• Maxtor – same Main Controller IC(The biggest chip on the board), for example 040111300.

• Hitachi – for 2.5" hd, it is the information on the small white label begin with OA..., for 3.5" hd, it is the same Main Controller IC, begin with OA...

• Samsung - same board number which is etched on the PCB, begin with BF41-, for example BF41-00303A.

• Fujitsu - same board number which is etched on the PCB, begin with CA***

Hard Drive PCB Swap Process:

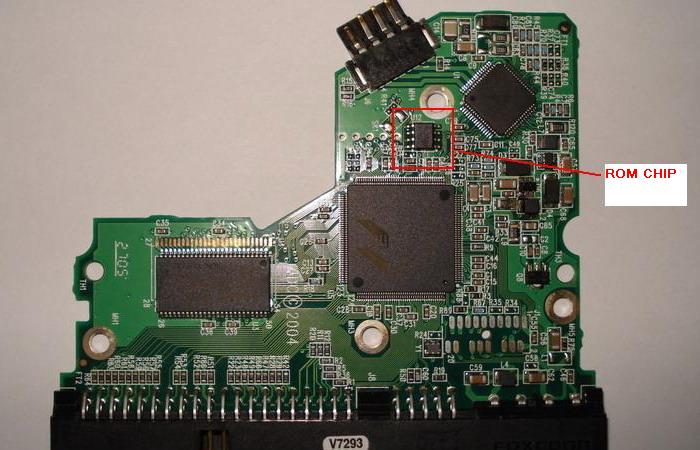

Remove the PCB from both hard drives with star screwdriver. Replace the damaged PCB with replacement one. If you HDD spins up, but can’t be recognized, you should also exchange the BIOS chip on it. If there is no matching 8pins BIOS chip on the PCB, it means the BIOS chip is integrated on the Main Chip IC, then you should remove the damaged PCB’s Main Chip IC to the donor PCB. It is more complex to exchange the Main Chip IC than exchange the BIOS chip. If you should do, please do several test on the PCBs which don’t have the important data.

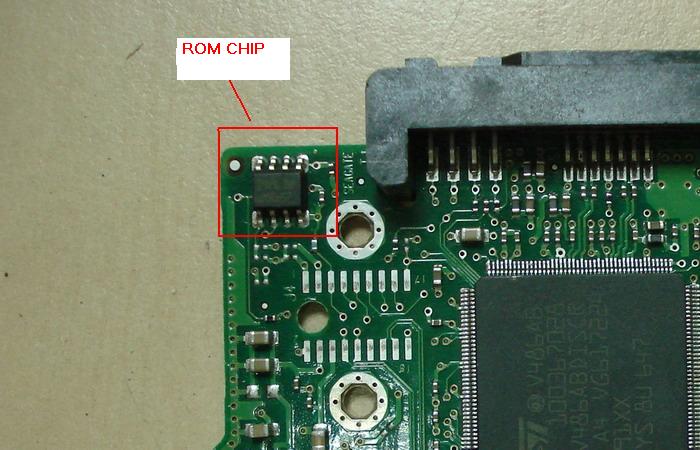

What is PCB’s BIOS(ROM) Chip?

All of the 8pins (4 pins on each sides) with 25P05VP, 25P10VP, 25F512, 25F1024, 25F1024AN, SST25VF512, SST25VF010, etc. are the BIOS chip. It is easy to be found because there are not many 8pins chips on the PCB.

In most cases, you should exchange the BIOS before you swap hard drive pcb. You should have certain technique and tools.

Where to buy hard drive pcb online?

There are many great PCB online stores sell all kinds of PCB for your data recovery needs! Such as http://www.drivestar.biz. We provide all kinds of PCB: Seagate, Western Digital, Maxtor, Samsung, IBM, Hitachi and Fujitsu. Always help you to find the marching PCB for your hard drive.

Note: You should know the hard drive failures are not always caused by PCB failure, swap PCB can’t guarantee to fix all of the hard drive problems.If the hdd pcb is damaged or burnt, need to replace it with the same model of pcb to make the hdd work.

1. For WD hdd, need to check the number on the pcb and the main chip.

The board number of pcb is 2060-701292-000 REV A

The board number of pcb is 2060-701335-003 REV B

The number of main chip is 88i6540-LFH

The number of main chip is 88i6545-TFJ1

For WD hdd, the ROM chip stores the firmware of the hdd (firmware for hdd is like operating system for computer), you need to change the ROM chip from original board to the replacement board, in order to make the replacement board compatible with your HDD.

For some new models of WD pcb (ROYL Series), it has no independent ROM chip, the firmware is inside the main chip, need some tools to read it from the original pcb and write to the replacement board, or swap the main chip.

2. For Maxtor hdd, need to check the number of main chip.

The number of main chip is 040111300

The number of main chip is 040125400

Most Maxtor hdd no need to replace the ROM chip, some needs.

3. For Seagate hdd, need to check the board number of pcb and main chip.

The board number of pcb is 100466725 REV A

The board number of pcb is 100422559 REV B

The number of main chip is 0750T 6727517

The number of main chip is 100367028

For Seagate hdd, also need to replace the ROM chip on pcb. Some models of pcb have no ROM chip, the firmware is stored in the main chip.

Hot air rework station

Use hot air rework station to remove the ROM (BIOS) chip from the original pcb.

The ROM (BIOS) chip is removed.

Solder the ROM (BIOS) chip on the Replacement pcb.

the following problems may be the pcb fault:

1, the hard drive does not spin up after power on;

2, the chip no change in temperature;

3, smoke and short circuit;

4, pcb components burn or connector damaged;

5, the computer cannot boot.

the following problems may be the hdd media fault:

1, the pcb is heating hot when the hard drive spins up;

2, the hard drive doesn't be recognized or very slowly;

3, the hard drive clicks or have bad sectors;

4, the initialization is very slowly or pending after start the computer.